Products

Residential Garage Door

SoarShine Garage Door Manufacturers was founded in 2017 and currently has over 60 employees. It is a comprehensive enterprise mainly engaged in new environmentally friendly building materials. It introduced technology from Australia and was the first in China to start researching and producing electric garage door products with international advanced levels.

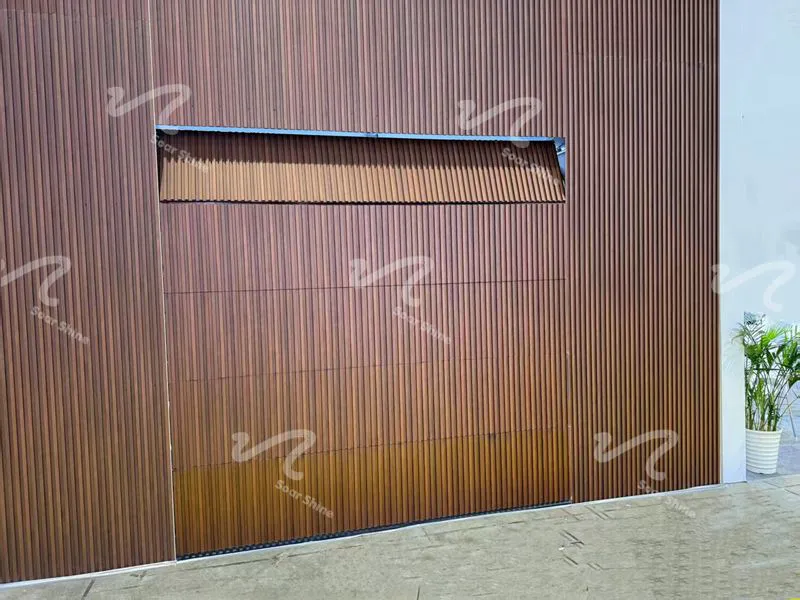

Constructed from premium 6063-T6 aluminum alloy, or featuring a steel frame with vertical wooden slats, or wood-grain steel panels.

Constructed from premium 6063-T6 aluminum alloy or smooth steel panels, with polyurethane foam insulation effectively blocking summer heat and retaining warmth in winter.

Minimalist Flat Wood Grain Garage Door

Constructed from premium 6063-T6 aluminum alloy or pre-treated wood-grain embossed steel, paired with tinted glass.

Constructed from premium 6063-T6 aluminum alloy or steel materials, featuring polyurethane foam insulation for effective heat wave isolation and winter warmth retention

Constructed from premium 6063-T6 aluminum alloy or steel materials, featuring a raised steel-molded panel design available in multiple colors and woodgrain finishes.

Full-View Aluminum Garage Door

Constructed from premium 6063-T6 aluminum alloy or steel frames, featuring flat glass, frosted glass, or tempered glass panels for easy installation and maintenance.

Constructed from premium 6063-T6 aluminum alloy or steel frames, featuring square-panel assemblies with customizable designs (solid-color frames/wood-grain panels).

Constructed from premium 6063-T6 aluminum alloy or steel, featuring die-cast steel panels available in multiple colors and woodgrain finishes.

Aluminum Alloy Grille Garage Doors

Constructed from premium 6063-T6 aluminum alloy with an aluminum grille panel, featuring a polyurethane insulation layer on the rear.

Industrial Door Products

Constructed with durable, low-maintenance double-sided steel panels filled with polyurethane foam, offering lightweight yet high-strength performance.

Constructed from premium 6063-T6 aluminum alloy paired with tempered glass panels, offering four tinted glass options.

Durable premium PVC construction paired with a high-speed tubular motor enables versatile application within factories and warehouses.

High-speed Turbine Rolling Door

Crafted with high-quality 6063-T13 aluminum alloy, it features a fast-response motor and offers lightweight, high-speed sectional lifting or turbine lifting.

Doors Opener

Industrial High-Speed Roll-Up Door Opener

√ Input voltage 0.75~2.2KW

√ Stepless speed regulation, opening speed 1m/s

√ LCD display panel, Torque reflection

√ Maximum applicable area ≤ 75 m²

Industrial Overhead Door Opener

√ Soft start Soft stop

√ Automatic rebound/stop against obstacles

√ Input voltage 220V/110V

√ LCD display panel,Torque reflection

√ Lifting speed of 0.4 m/s

01. Submit Requirements

Including door type (garage door/industrial lift door/commercial door), installation scene (such as villa garage, factory door opening, shop entrance), size specification, material preference (steel/aluminum alloy/solid wood, etc.), special function (insulation/fire prevention/intelligent control, etc.) and project requirements. The customizer provides precise measurement of the opening dimensions (width, height, depth), wall structure (brick-concrete/steel structure/other), on-site environment (whether there are obstacles, power supply location, ground flatness), and records the installation conditions (such as whether there is reserved track space, strength of load-bearing beams, etc.) This includes the purpose of the door body (elevated garage/industrial workshop/warehouse logistics door/commercial door), installation location (indoor/outdoor), opening method (electric/manual), budget range and special requirements (such as insulation, wind resistance, fire resistance and anti-theft grades).

02. Design & Technical Confirmation

Based on the survey data and requirements, the customization party will provide a detailed design plan, including door structure drawings, dimension details, material specifications, hardware selection (tracks, motors, spring systems), and safety device configuration (such as emergency stop buttons and infrared anti-pinch sensors). Technical parameter confirmation: For industrial doors, the wind pressure resistance rating (based on the wind speed of the installation area), opening and closing speed, and motor power (matching the door weight) must be specifically defined; for garage doors, operating noise and insulation coefficient (such as PU foam filling for northern regions) must be confirmed.

03. Quotation & Contract Signing

Based on the technical confirmation plan, calculate costs for raw materials, custom processes, labor, etc., and provide a detailed quotation within 2 business days (including product specifications, unit prices, total costs, and payment terms). The customization party shall calculate costs (materials, processing, transportation, installation, after-sales service) based on the final plan and provide a detailed quotation. Upon confirming cooperation, a formal contract will be executed, specifying door parameters, delivery timeline, installation schedule, payment terms (typically a 50% deposit of the total amount), acceptance criteria, and warranty provisions.

04. Production & Manufacturing

Custom manufacturers initiate production according to technical drawings: This includes sheet metal cutting, bending and forming, surface treatment (such as acid washing and phosphating, high-temperature spraying), and component assembly (motors, tracks, balancing systems), ensuring the load-bearing structure of industrial doors and the smooth operation of garage doors meet standards. Critical quality inspections: These cover door panel flatness, weld strength (industrial doors), and anti-corrosion treatment of hardware components, preventing dimensional deviations during installation.

05. Pre-installation Test & Factory Inspection

After the door assembly is completed, pre-installation testing is conducted at the factory: Simulating operational trajectories, inspecting whether motor operation is smooth, safety devices are responsive (e.g., obstacle-detection rebound function), and sealing performance (door gap clearance). A factory acceptance report is issued: Test data is recorded, and shipment is arranged only after confirming compliance with contractual technical requirements.

06. Inspection and Shipment

Upon completion of the finished product, the customer will conduct a video inspection or designate a third-party inspection agency. After confirmation of satisfaction, the final payment will be made, and shipment will be arranged. Simultaneously, video installation guides and after-sales contact information will be provided to ensure smooth subsequent installation.